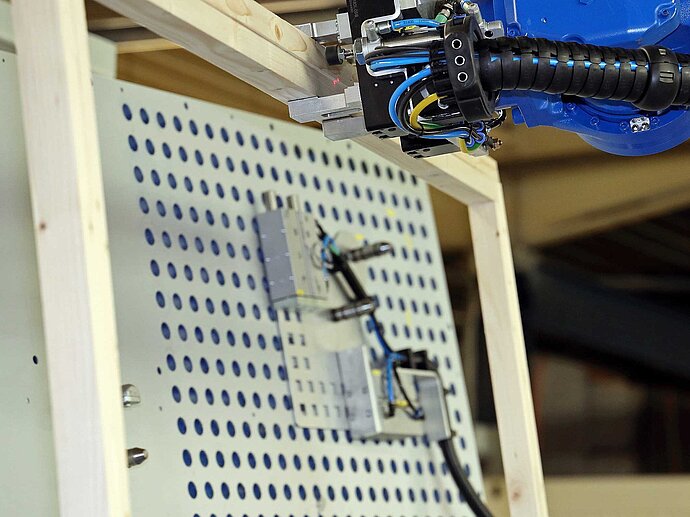

Especially in connection with door or window production, the cell opens up a wide range of possibilities. "Every door or component manufacturer surely knows the problem with special designs that cannot be realised economically within a series production", says Bürkle's managing director Olaf Rohrbeck. "This is where our cell comes in, which can flexibly process such special sizes".

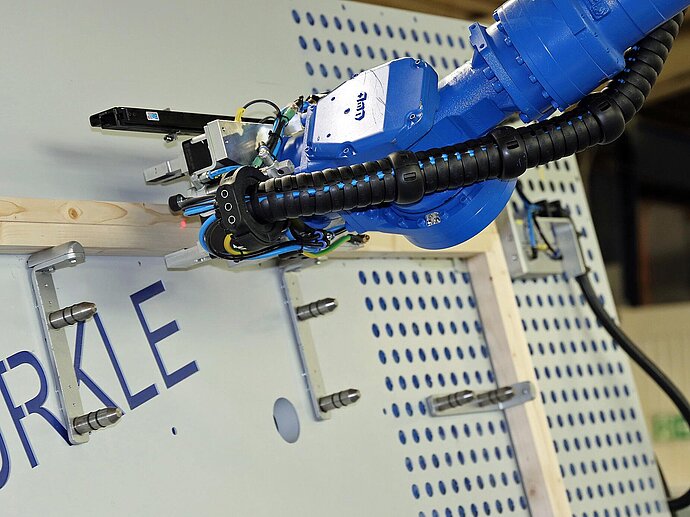

The processing cell is designed for the door production. It measures the bolt lengths, cuts the bolts to length with a crosscut saw and assembles them with glue and tacker to an empty frame. Cover layers and the inlay material can also be fed, depending on how far the door blank is to be prepared.