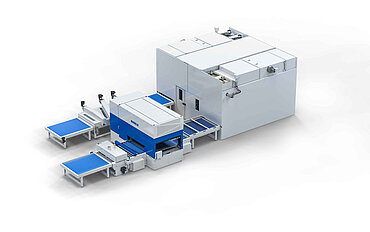

The US interior designer and timber processor Eastern Millwork (EMI) is headquartered just outside Manhattan. The location offers the company a great advantage, since New York and New Jersey are home to a vibrant design and architecture scene. But at the same time, investments in machinery must also be considered against the backdrop of scarce land space. When EMI was looking for a new spray-coating system, compactness and flexibility were therefore the most important factors. Both requirements were met by the Bürkle Spray coating machine and line.

Madison Square Garden, John F. Kennedy Airport, New York Stock Exchange, Goldman Sachs Headquarters, Times Square Tower, Prada, Salvatore Ferragamo or the offices of The New York Times – to name just a few from EMI's prominently stocked list of references. Established in 1992 by Andrew Campbell and run by him as President and CEO, the company currently employs 75 people. Architects in particular are keen to use EMI's technical facilities as an extension of their studio as here they can often explore how architectural dreams can be turned into structural reality. Complex tasks are therefore daily business for EMI. At the same time, this close networking with the world of architecture creates synergies and ensures knowledge transfer.

Almost all leading German machine and system manufacturers in the industry are represented in Eastern Millwork’s machine park. The production is fully automated; all necessary information circulates digitally through the company. A proprietary system tracks orders from production to delivery and on-site installation using barcodes and RFID chips. “People sometimes jokingly refer to us as a tech company that happens to be in the timber processing business," says Campbell. The objective is not to be the biggest, but to be recognised as the best. Productivity and earnings are continuously increasing, thus ensuring the company’s growth. Ever since his Tech Tour, Campbell has been interested in Germany’s dual education system. For him, young German engineers represent the fusion of technological insight and traditional craftsmanship. Some of them he hired “on the spot” to work at EMI at the time. In partnership with Hudson County Community College in New Jersey, he has been offering a four-year paid higher education and vocational training programme called “Holz Technik” for just under three years.

EMI covers all the costs of the training and the students are paid a salary from the very beginning. Paid leave, an allowance for private pension provision and non-contributory health insurance round off the package. Considering that American students typically finish their higher education with a high five-digit dollar amount of debt, the entrepreneurial and sociopolitical foresight of EMI's owner is evident. “With this programme, we are providing a pool of engineers with diversified and unique skills that we are looking for,” says Campbell.

For the use of surface materials and their finishing, keeping an eye on architectural trends is enormously important for EMI. Trends are continuously changing. Hospitals, for example, do not want to look like just any conventional hospital, especially not in their reception areas; they strive for the atmosphere of upscale hotel lobbies. “Haptic properties, soft touch and scratch-resistance are asked for here, and are becoming increasingly important to planners and investors. In terms of colours, oak, walnut and white-pigmented timber is en vogue,” says HeikoSieling. He has been working as the company's chief estimator for nearly two decades and has also been in charge of EMI’s operative business as COO for a good five years. As a graduate of the Hildesheim School of Design and Timber Technology, he is one of Campbell's highly valued professionals trained in Germany, whom he was able to recruit to work with him.

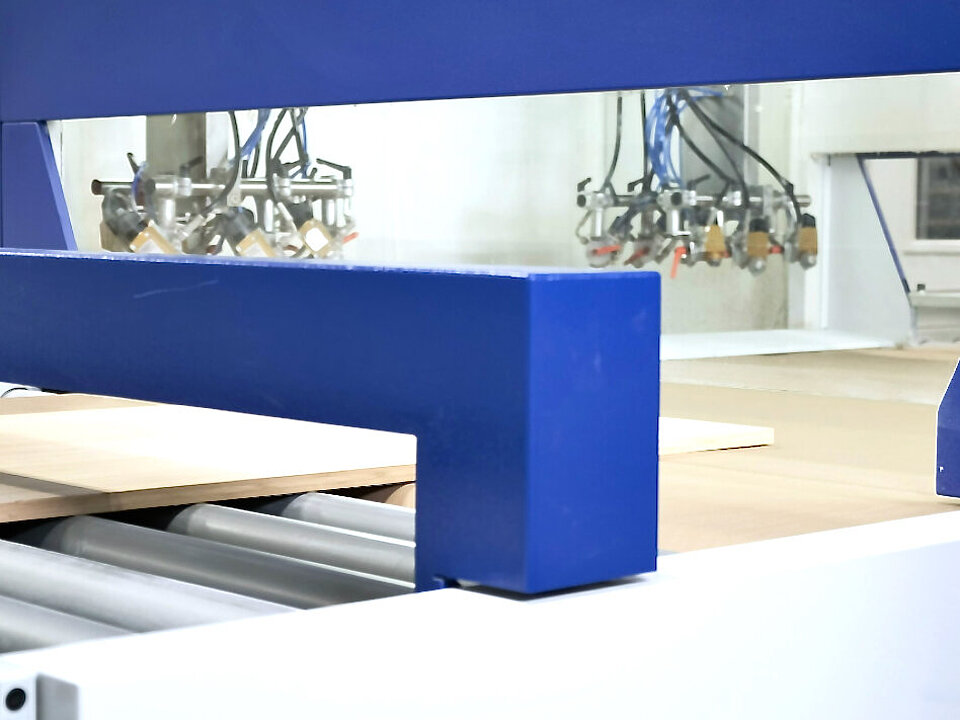

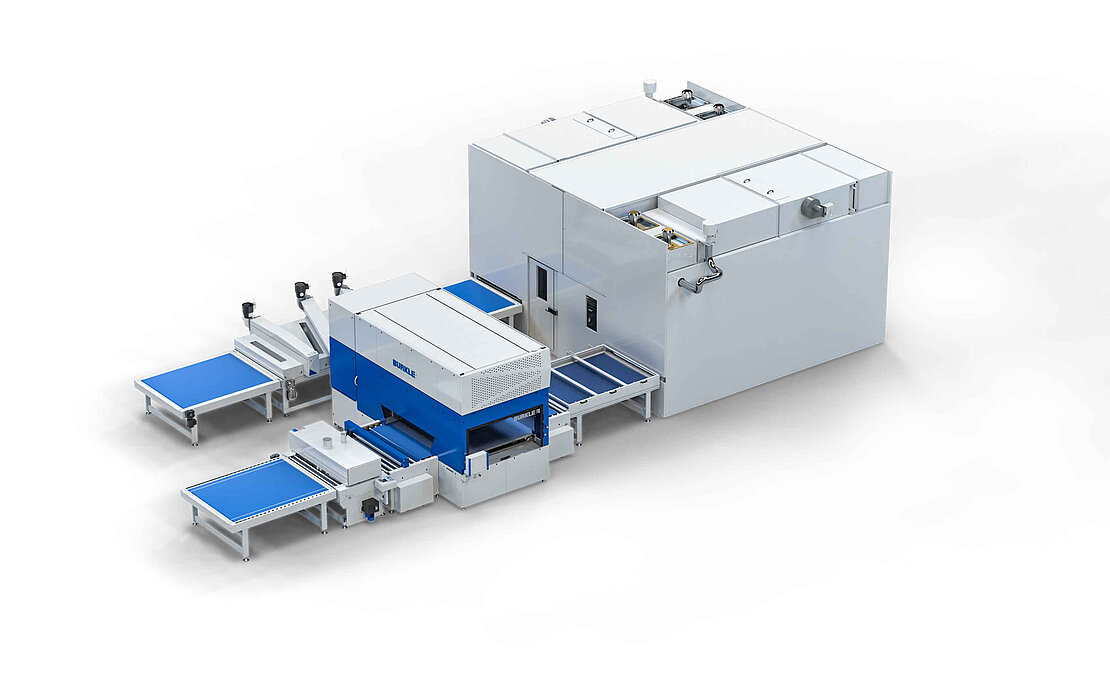

The analysis of the surface materials to be used and their further processing are also important for EMI for another reason: Land and building costs in the New York City periphery are enormously high, so space is scarce and must be optimally utilised. Investments in machinery must also be considered under this aspect. “We manufacture a lot of wall and ceiling panelling with surfaces that need to be coated. To have an advantage over our competitors, we also need to cut labour costs. We thus had to find a system that is compact yet meets all other requirements with a high degree of flexibility,” explains Sieling.

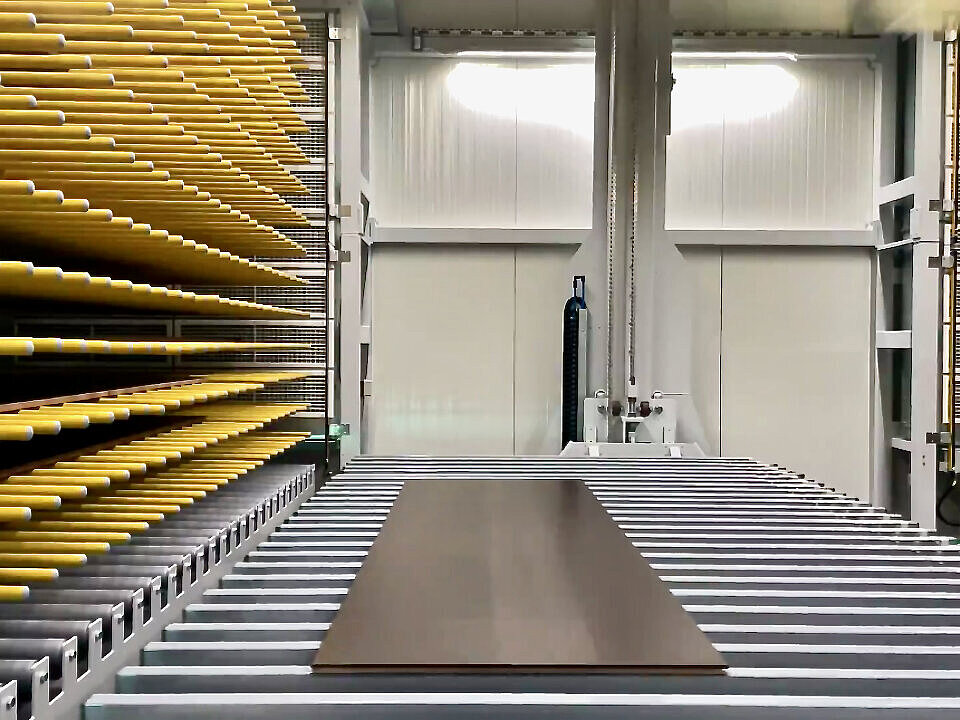

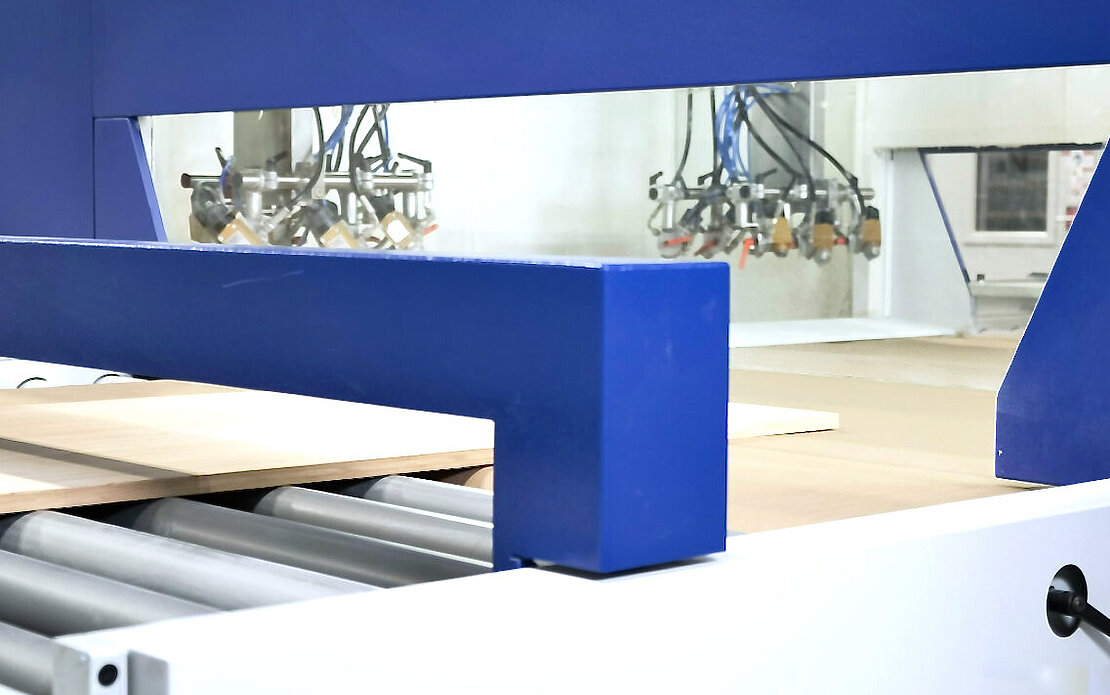

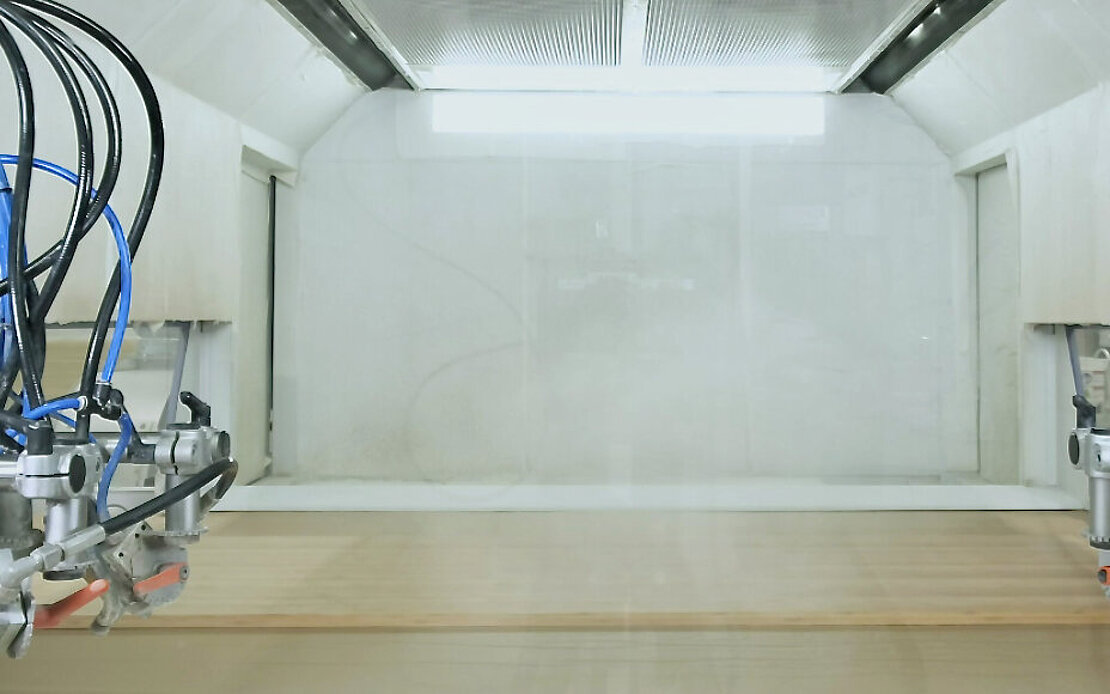

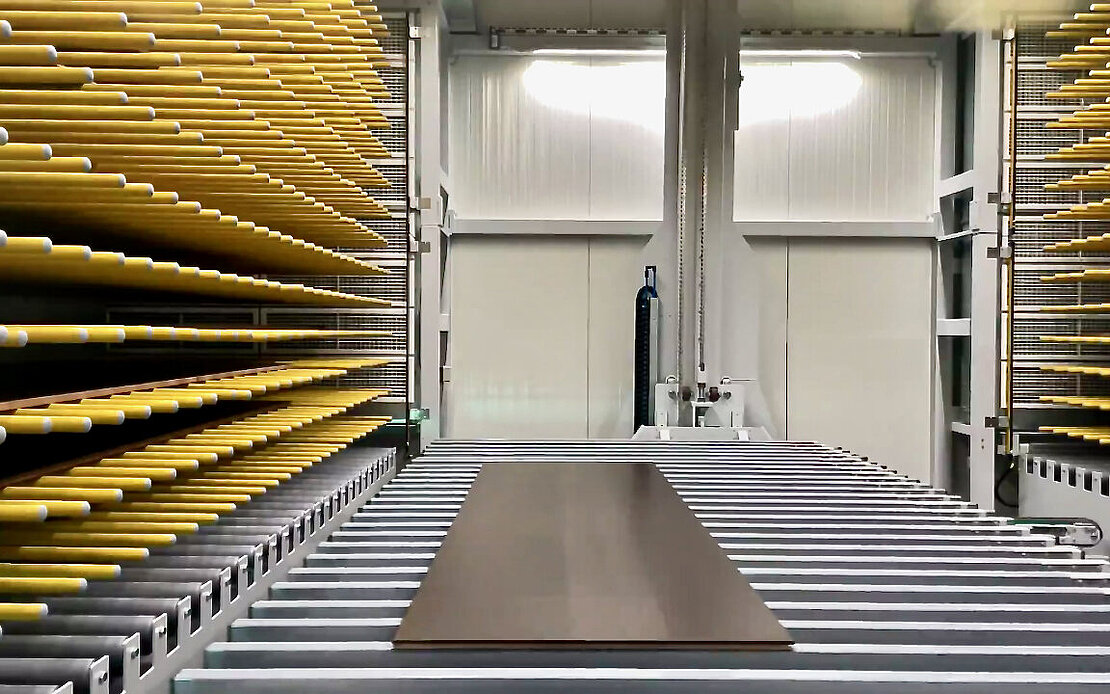

Following extensive research and many discussions, EMI decided on a spray coating system from Bürkle. Thanks to its universal application possibilities, Eastern Millwork uses the system for the coating of almost all surfaces. Whether water-based or solvent-based coatings, high-gloss coatings or even stains – Sieling and his team are very impressed by the system’s. “The Bürkle easy- Dry rack deck dryer, located between spray coating machine and UV dryer, offers great benefits. The system levels allow us a high degree of individuality. We can thus easily achieve different drying times for different types of coating and coating systems,” says Sieling, characterising one of the system’s special technical features.

This is complemented by an exceptionally sturdy design and high-quality machine components. Vibrations are eliminated almost fully. The cooperation with the Bürkle team from headquarters in Freudenstadt and the fitters from the US branch in Greensboro was absolutely trouble-free. “We need partners who can adapt to our requirements and implement them perfectly. This is the only way for us to compete successfully and grow as a company. In the field of spray coating, Bürkle is the ideal choice for us in every respect”, Sieling states. On a side note, he also mentions the good cooperation in the laminate sector with the market-leading US manufacturer Wilsonart, who also uses a Bürkle system in its plant in Temple, Texas. On a PUR laminating system, Wilsonart produces laminates that EMI also likes to use. Not only Sieling and his team seem to be convinced of the Freudenstadt machine and engineering “Made in Germany”.