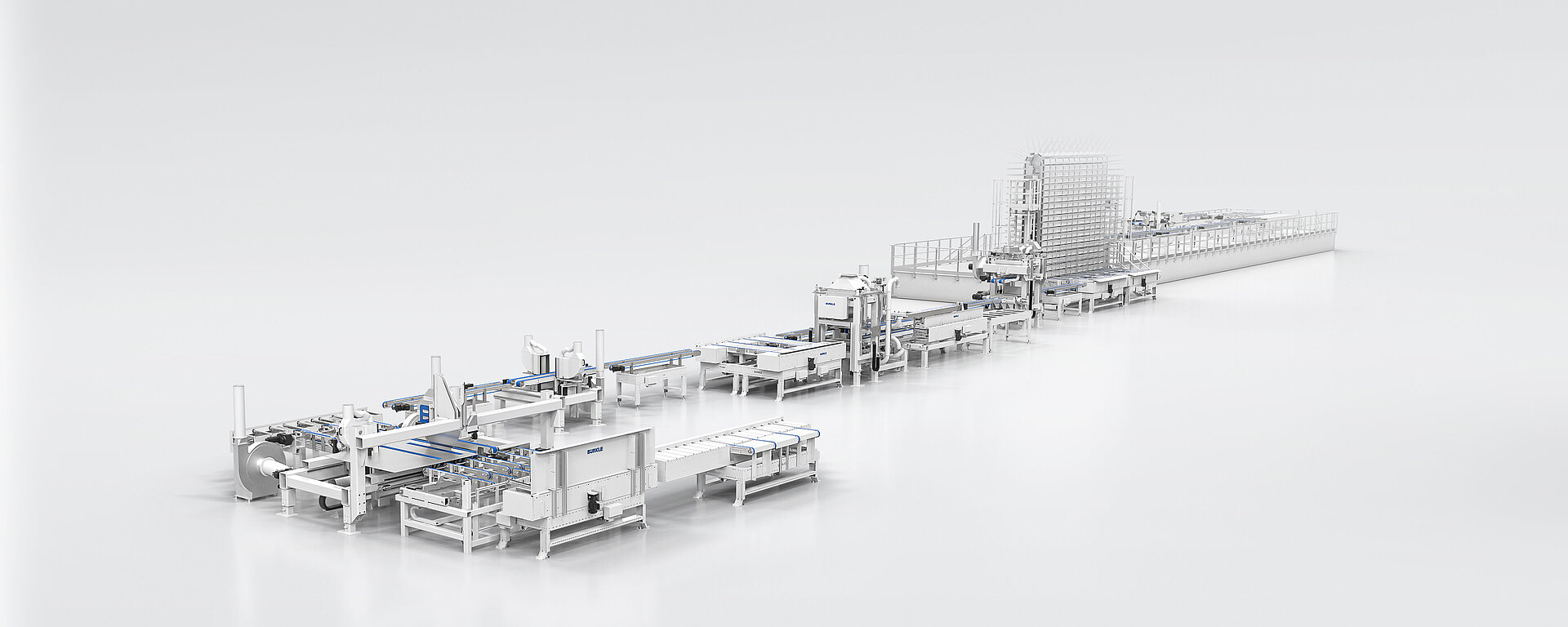

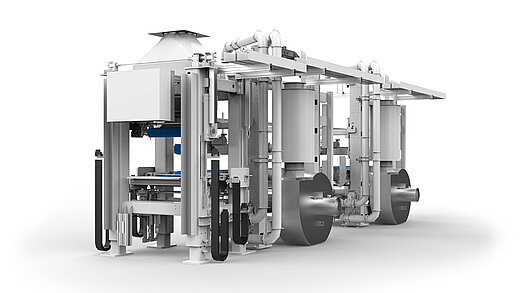

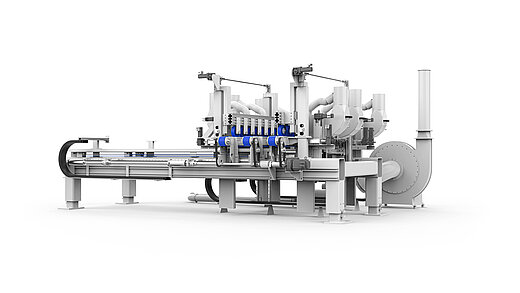

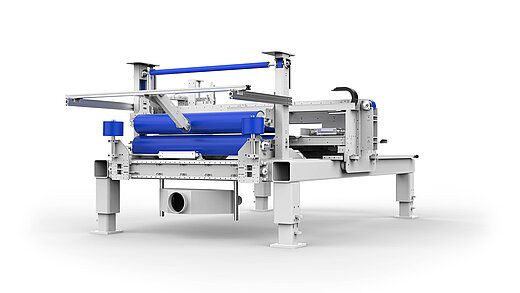

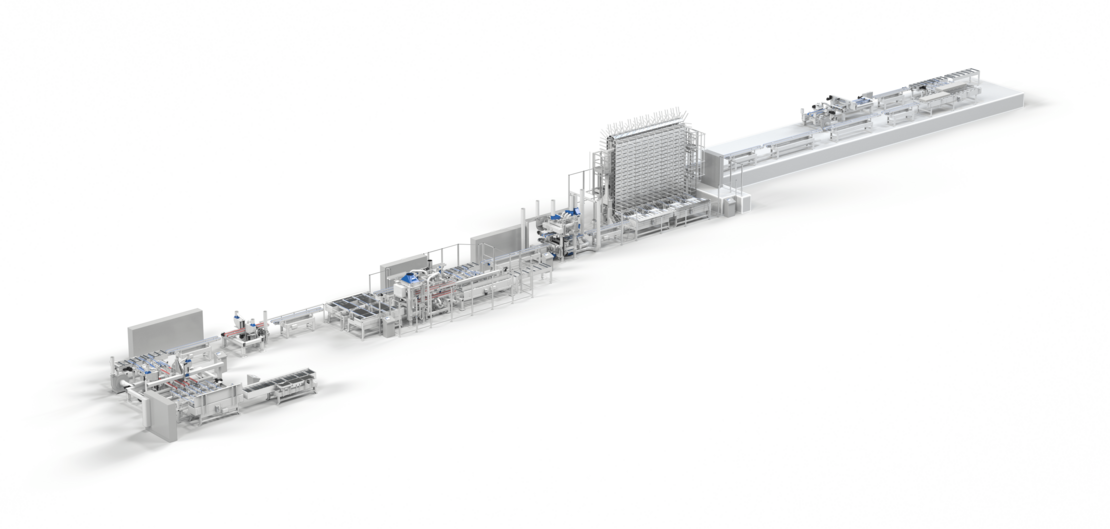

Insulation and foam downstream lines

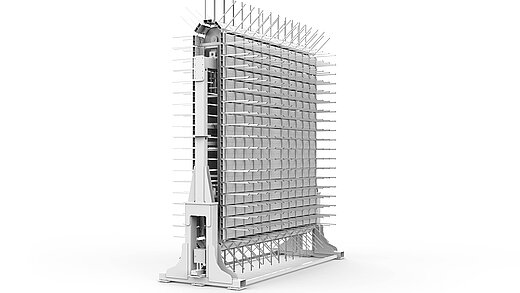

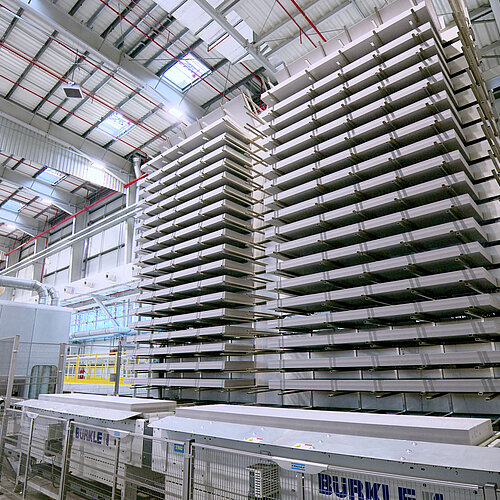

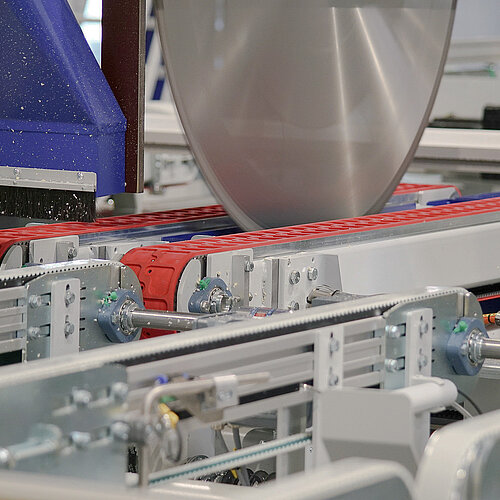

Highly developed technology: XPS and EPS downstream lines from BÜRKLE

The use of insulation boards to reduce the energy demand of new or existing buildings is an important part of environmental and climate targets. With the thermobonding lines, BÜRKLE creates the possibility to produce insulation boards with excellent insulation properties and at the same time lower insulation board thicknesses.