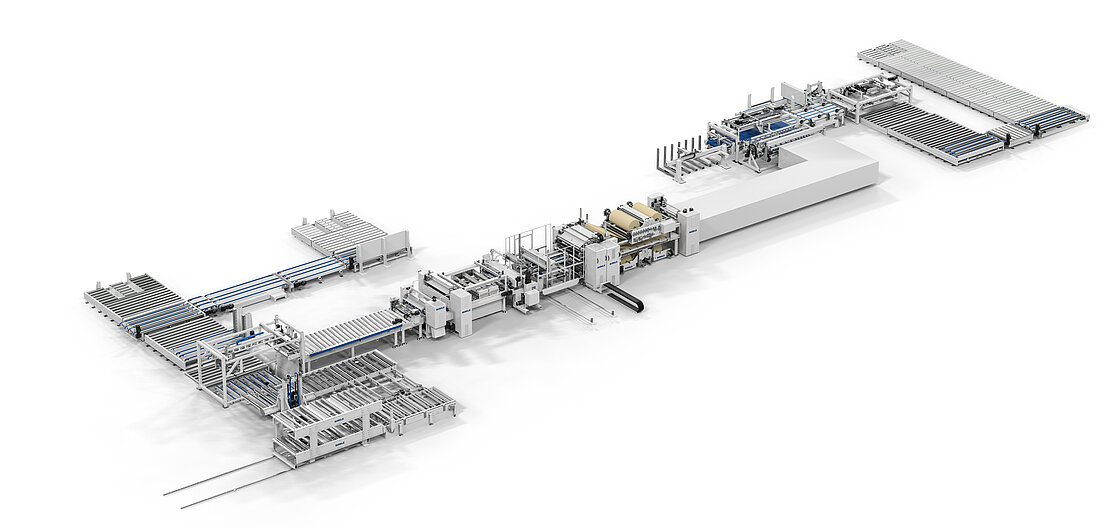

Laminating lines

Leading production technology: our laminating lines

For unique surfaces and the highest demands: our laminating lines combine state-of-the-art technology with individual planning to take your production processes to a new level. Whether for small series or large-scale industrial production - we develop customized solutions that combine efficiency, quality and innovation. Put your trust in BÜRKLE when it comes to pioneering technologies and perfect results.