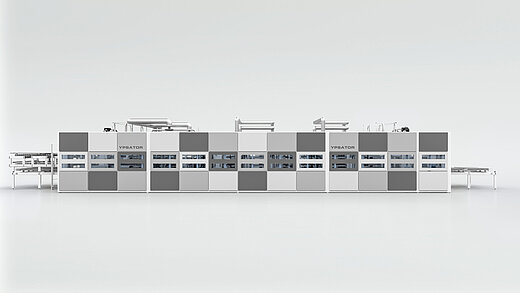

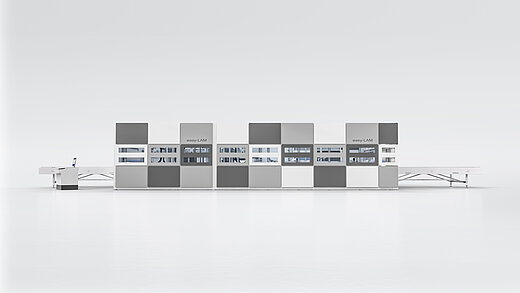

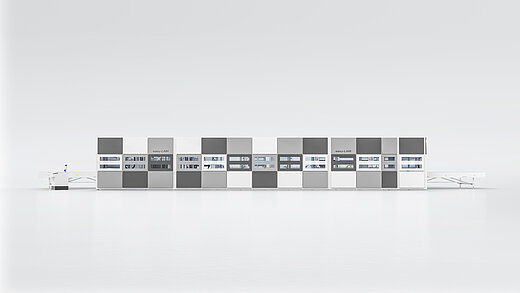

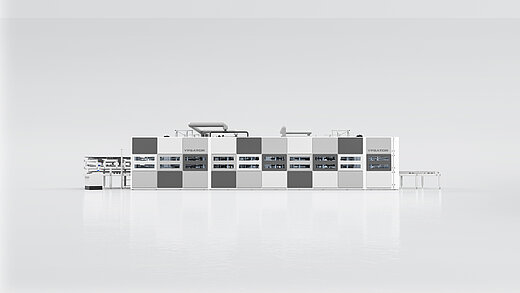

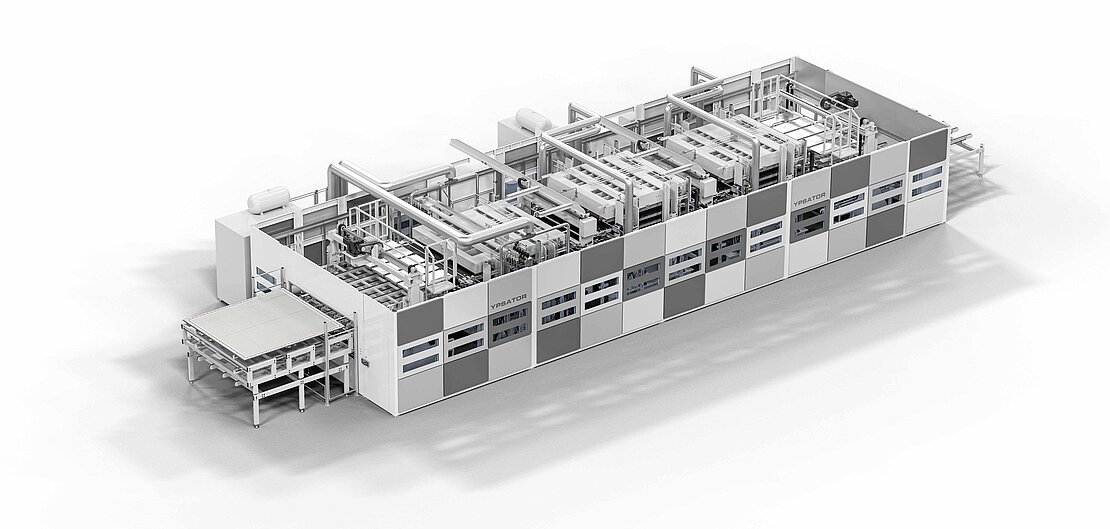

Solar modules

Laminators for the production of solar modules

The environmentally friendly generation of energy requires the development of new technologies and application possibilities. But not only the development of these technologies, but also increasingly efficient production processes will be necessary in the future. Therefore, the focus of our SL and VFF processes for the production of glass backsheet and glass-glass modules is on the most efficient and highest quality lamination of photovoltaic modules.