Plastic cards

Laminating lines for the production of plastic cards

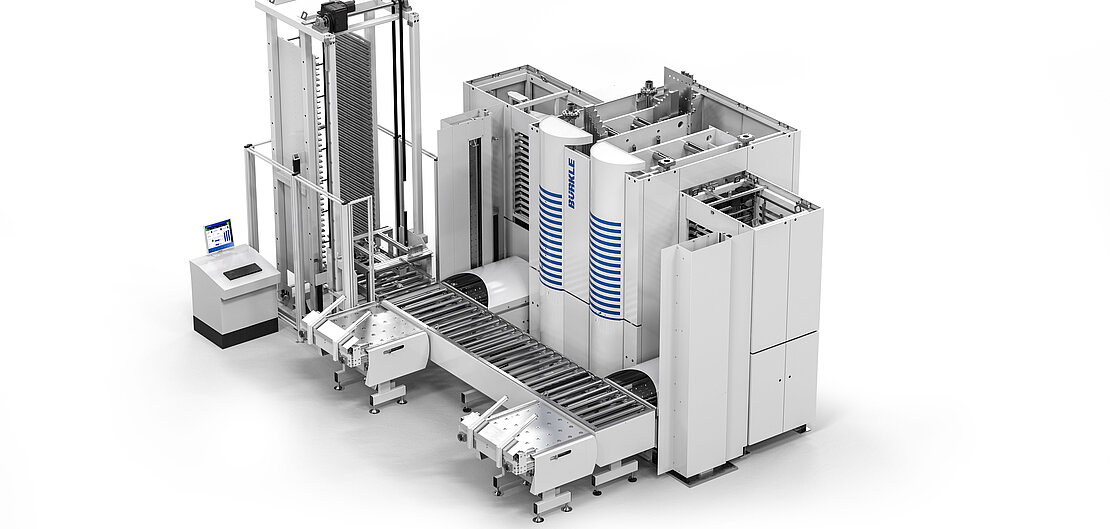

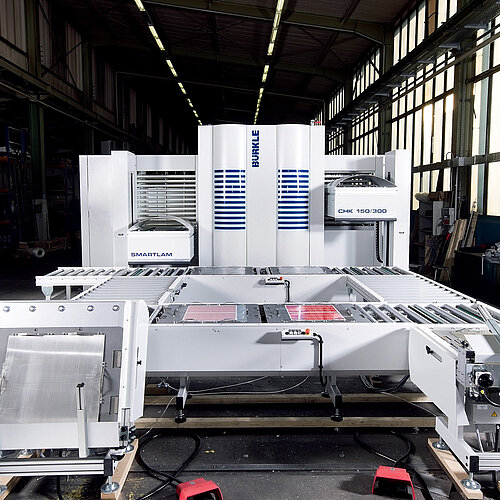

Credit cads, ID cards, conventional and contactless cards: Our state-of-the-art technologies for the production of plastic cards enable us to master the everyday processes and challenges involved in the manufacture of cards of all kinds. With the modular design of our SMARTLAM laminating lines, we offer customers an individual line design for small to large production capacities. Your production requirements are comprehensively met and implemented by our SMARTLAM line